- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

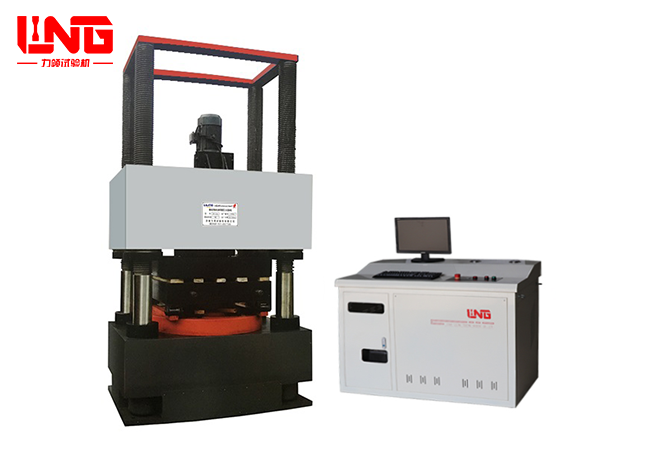

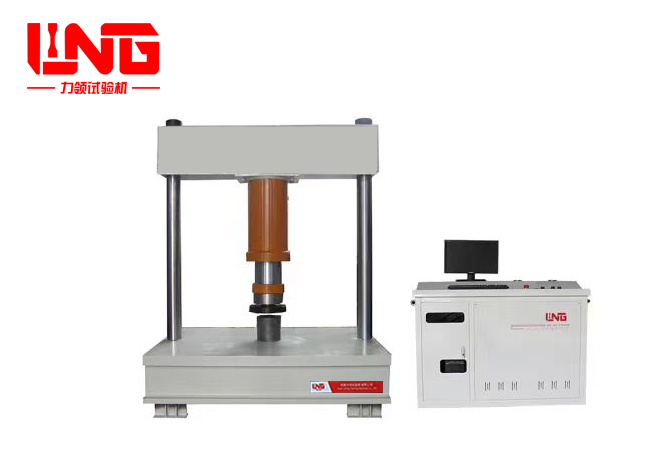

Máquina de prueba de presión automática de control de microordenador de 500 toneladas

La máquina de prueba de presión servo electrohidráulica controlada por microordenador YAW-5000 se utiliza principalmente para probar las propiedades mecánicas de los rodamientos de goma y los productos amortiguadores. Puede probar la resistencia a la compresión, el módulo de compresión, la adhesión al cizallamiento, el antienvejecimiento, el coeficiente de fricción, el ángulo de rotación y otras pruebas de productos de rodamientos de goma. También se puede utilizar para detectar la deformación axial y radial del rodamiento de goma de disco de puente bajo prueba de carga. La prueba se calcula de acuerdo con la fórmula relevante de JT / T 4-2004 en la industria del transporte, y también se puede probar de acuerdo con el método de prueba estándar de caucho.

Introducción

Introducción del producto:

La máquina de prueba de presión electrohidráulica controlada por microordenador YAW-5000 adopta un cilindro de émbolo de varilla única para aplicar la fuerza de prueba, adopta un sistema de control de servo electrohidráulico de carga coordinada de bucle cerrado multicanal, carga hidráulica multietapa controlada y coordinada por microordenador, carga continua estable, mantenimiento de la fuerza de prueba multietapa, carga continua y estable automática, retención automática de carga, recopilación y almacenamiento automáticos de datos, almacenamiento y dibujo de curva. Informe de prueba de impresión automática, proceso de prueba de control oportuno de computadora, fuerza de prueba de pantalla y curva de prueba, operación simple y confiable, fácil de operar.

Parámetros

Parámetros técnicos:

1. Fuerza de prueba máxima: 5000kN;

2. Rango de medición de la fuerza de prueba: 2% -100% (todo el proceso no se divide, equivalente a seis engranajes);

3. Precisión de medición de la fuerza de prueba: ±1% del valor de indicación de la fuerza de prueba;

4. Velocidad máxima de desplazamiento sin carga del actuador: 0-50mm / min

5. carrera del actuador: 300 mm; Resolución (mm): 0.01

6. Precisión de la medición del desplazamiento: mejor que ±0.5%Fs;

7. Resolución de medición de deformación (mm): 0,01

8. espacio de ajuste de prueba (mm): 0 ~ 1500;

9. espacio máximo de prueba: 1500 mm;

10. Tamaño de la placa de presión superior: 600mm × 600mm;

11. Tamaño del disco inferior: 600mm × 600mm;

12. Velocidad de elevación de viga: 200mm / min;

13. Rango de control de la fuerza de prueba isocinética: 0.5kN / s ~ 25kN / s (precisión de control 1%);

14. Rango de control de desplazamiento constante: 0,5 mm / min ~ 30 mm / min;

15. Modo de control y procesamiento de datos: sistema de control servo de computadora y adquisición y procesamiento de gráficos de datos (fuerza de prueba, desplazamiento);

16. Método de medición de la fuerza: medición de la fuerza del sensor de carga de alta precisión;

17. Con el elemento de sellado combinado de baja amortiguación, la fuerza de prueba permanece estable y fiable.

18. Modo de control: carga hidráulica, control de circuito cerrado servo electrohidráulico, medición del sensor de presión del aceite de alta precisión, pantalla.

19. Altura del anfitrión: 3800mm;

20. Tamaño de la máquina: aproximadamente 1200 * 950 * 3800 mm