- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

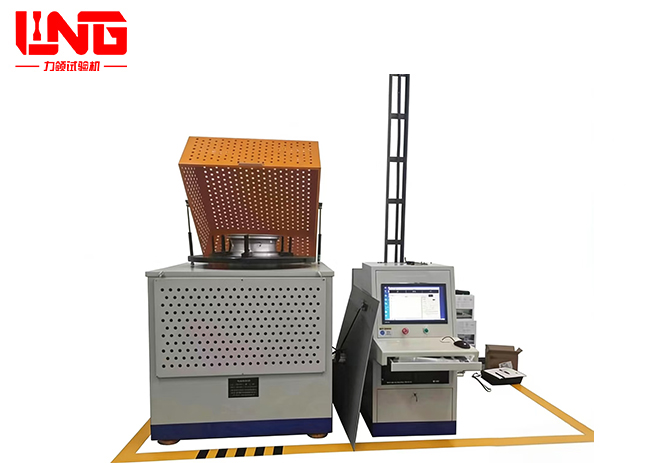

Máquina de prueba de fatiga electrónica controlada por ordenador de doble estación

La máquina de prueba de fatiga electrónica controlada por microordenador de doble estación se utiliza principalmente para probar las propiedades mecánicas dinámicas de metales, materiales no metálicos y piezas. Equipado con diferentes accesorios, puede completar las pruebas de propiedades mecánicas de piezas de prueba como fatiga por tracción, fatiga por compresión, durabilidad, vida útil, etc. Los parámetros de rendimiento del producto cumplen plenamente con el código de verificación nacional de la máquina de prueba de fatiga axial JJG556.

Introducción

Introducción del producto:

1. La máquina de prueba de fatiga electrónica controlada por microordenador de doble estación tipo LPD-5-2 se utiliza principalmente para probar las propiedades mecánicas dinámicas de materiales y piezas metálicas y no metálicas. Equipado con diferentes accesorios, puede completar las pruebas de propiedades mecánicas de piezas de prueba como fatiga por tracción, fatiga por compresión, durabilidad, vida útil, etc. Los parámetros de rendimiento del producto cumplen plenamente con el código de verificación nacional de la máquina de prueba de fatiga axial JJG556.

2. Tiene dos modos de control de fuerza de prueba y desplazamiento.

3. El software electrónico de prueba de fatiga dibuja y muestra automáticamente varias curvas de prueba, como la curva de fuerza-tiempo de prueba, la curva de desplazamiento de fuerza de prueba, la curva de tiempo de desplazamiento. Hay varias curvas de forma de onda tales como onda sinusoidal, onda triangular, onda oblicua, etc., después de la finalización de la prueba, la curva de prueba se guarda automáticamente y los datos de muestreo de prueba se emiten de acuerdo con el informe de prueba estándar.

4. Pruebe y proporcione datos de acuerdo con las normas relevantes o las normas de la industria, registre el número de ciclos de fatiga, valores límite de fatiga y otros parámetros de prueba.

Parámetros

Parámetros técnicos:

1. Número de estaciones: 2 estaciones en paralelo

2. Simplex fuerza de prueba estática máxima: 5KN

3. Simplex fuerza de prueba dinámica máxima: 4KN

4. Rango de garantía de la precisión de la fuerza de prueba: fuerza de prueba estática máxima 2% -100%

5. Error de indicación de la fuerza de prueba estática: dentro del ±0,5%

6. Error de indicación de fuerza de prueba dinámica: dentro del ±2%

7. Frecuencia de prueba: 0.1-20Hz

8. desplazamiento máximo, amplitud: 300mm, ±150mm

9. Resolución de desplazamiento: 0.001mm

10. Precisión del desplazamiento: dentro del ±0,5%

11. Modo de control: control de bucle cerrado del desplazamiento y la fuerza de prueba;

12. forma de onda de prueba: onda sinusoidal, onda trapezoidal, onda triangular y onda personalizada

13. espacio de altura de prueba (distancia entre accesorios): 10-300mm

14. Modo de ajuste de altura del espacio de prueba: control manual de la caja del botón pulsador, telescópico del cilindro eléctrico

15. Instalación: placa de presión especial para la compresión de resorte

16. Fuente de alimentación total: 380V ± 10%, 50Hz, 4KW + 380V ± 10%, 5