- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

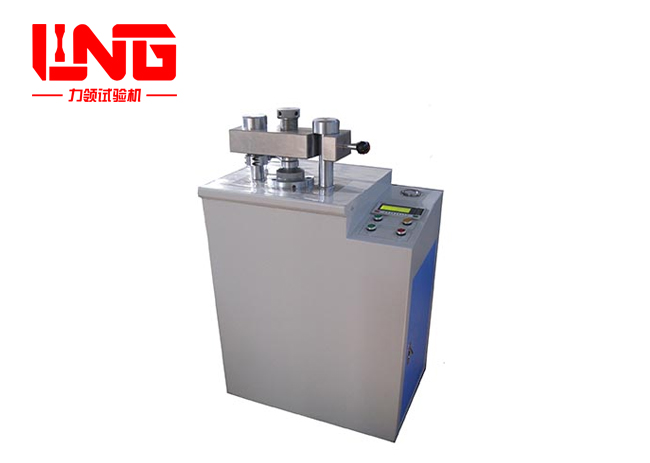

Tipo de control de servo de la máquina de prensa de muestras

El prototipo de prensa desarrollado y producido por Jinan Force Leading Testing Machine Co., Ltd. está especializado en el análisis de composición de metalurgia, metales no ferrosos, minerales, cemento, cerámica, campos de materiales electrónicos y el polvo prensado en piezas de prueba para equipos de soporte de espectrómetros de fluorescencia de rayos X.

Introducción

Presentación del producto:

El prototipo de prensa desarrollado y producido por Jinan Liling Testing Machine Co., Ltd. está especializado en el análisis de composición de metalurgia, metales no ferrosos, minerales, cemento, cerámica, campos de materiales electrónicos y el polvo prensado en piezas de prueba para equipos de soporte de espectrómetros de fluorescencia de rayos X. El equipo es nuevo en apariencia y compacto en estructura, que se puede aplicar a anillo de acero, ácido bórico, taza de aluminio, polietileno de baja presión, anillo de plástico y otros moldes, y puede reemplazar productos extranjeros similares. La máquina de prensa adopta el modo interno para prensar muestras, y tiene procedimientos de presión lenta y retirada lenta del molde, lo que es propicio para garantizar la velocidad cualificada de las muestras de prensa, y la fuente de alimentación de control adopta un voltaje bajo de 24V, lo que es más seguro para trabajar.

Máquina de prensa de la serie LCY, utilizando el modo interno, desplazamiento de la cabeza 110mm. Se puede usar para ácido bórico, anillo de acero, taza de aluminio, anillo de plástico, polietileno de baja presión y otros tipos de prensado de muestras. El control del servomotor tiene un programa automático de alivio de presión lenta y lenta, lo que mejora la calidad del prensado de la muestra. Programa de presión lenta automática: en el golpe vacío, la cabeza rápidamente arriba; A medida que el indentador se aproxima a la muestra, el indentador comienza a subir lentamente para alcanzar el valor de presión establecido. De esta manera, el aire en la muestra se puede exprimir lentamente, y la muestra se puede tensionar uniformemente para mejorar la calidad de la muestra. Programa automático de alivio de presión lento: Cuando termina la retención de presión, el alivio de presión comienza lentamente y la cabeza de presión baja lentamente. (Debido a que al presionar la muestra, se forma un vacío entre el indentador y la superficie de la muestra, si el indentador desciende rápidamente, la muestra se dispersará.) Cuando el indentador sale de la superficie de la muestra, el indentador desciende rápidamente para mejorar la eficiencia del prensado de la muestra. Programa de autoprotección del aumento del punto: Cuando el aumento del punto, el programa preestablece la presión de autoprotección, para alcanzar el apagado automático de presión, para evitar daños al mal funcionamiento del molde del equipo. Además, se utiliza un módulo de tubería hidráulica integrado especialmente diseñado en el sistema hidráulico, lo que no solo hace que el montaje sea más conveniente, sino que también reduce la posibilidad de fugas de aceite.

Parámetros

Especificación técnica:

|

Especificación |

Detalles del modelo LCY-40SF |

|

Presión máxima |

40 toneladas |

|

Tipo de molde |

Ácido bórico |

|

Distancia entre columnas |

240 mm |

|

Carrera máxima |

100 mm |

|

Tiempo de espera |

Ajustable arbitrariamente |

|

Alimentación eléctrica |

220V ±10% |

|

Potencia nominal |

2.3 kW |

|

Dimensiones externas |

750 × 650 × 1000 mm |

|

Peso neto |

450 kg |

|

Temperatura ambiente |

5~40 ℃ |