- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

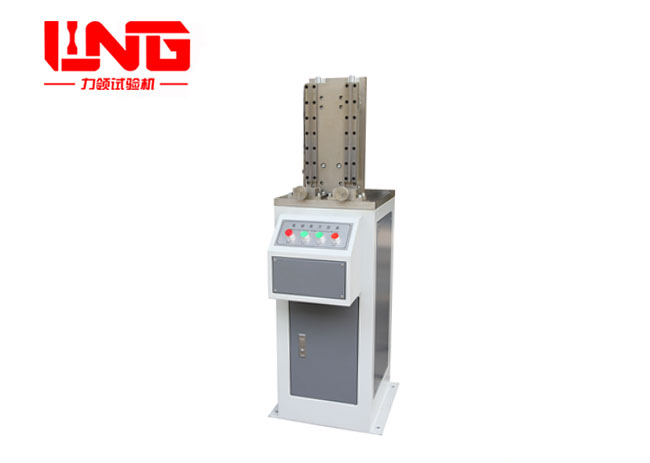

Máquina de brochado eléctrica de doble hoja de muesca de especímenes de impacto CSL-B

La máquina de brochado eléctrica de doble hoja de muesca de muestra de impacto CSL-B es la única herramienta en China que puede producir muescas de muestra de impacto Charpy cualificadas excepto para la molienda de curva óptica. Debido al principio de procesamiento de formación en una etapa, las muescas producidas tienen una buena uniformidad.

Introducción

Introducción del producto:

La máquina de brochado eléctrico de doble cuchillo de muesca de muestra de impacto CSL-B es la única herramienta en China que puede procesar muescas de muestra de impacto Charpy cualificadas, excepto para molidoras de curva óptica. Debido al principio de procesamiento de formación de una sola vez, las muescas que procesa tienen buena uniformidad.

Esta máquina de brochado adopta transmisión de tornillo de bola de alta precisión y rieles de guía lineales como soporte. Esta estructura asegura la estabilidad de la herramienta de brochado y la precisión geométrica de la muesca. Este producto está equipado con una herramienta de brochado de doble estación, que puede procesar dos muescas de muestra al mismo tiempo: una en forma de V (2 mm de profundidad) y una en forma de U (2 mm de profundidad) (también son posibles dos muescas en forma de V o dos en forma de U). Ya sea procesando muescas en forma de V o en forma de U, no es necesario cambiar la herramienta. Sólo tarda 10 segundos en procesar la muesca de la muestra una vez, lo que es fácil y fiable de operar. La herramienta de brochado de esta máquina de brochado está hecha de material W18Cr4V, que tiene alta dureza y buena resistencia al desgaste. Cada herramienta puede procesar más de 20.000 muestras.

Esta máquina de brochado cumple con GB 2106-80 "Método de prueba de impacto de Metal Charpy (muesca en V)" y GB/T 229-2007 "Método de prueba de impacto de muesca de Metal Charpy". Si la estructura se cambia y las partes relevantes se reemplazan, también puede cumplir con los requisitos de las normas internacionales relevantes como las normas americanas y europeas ASTM E23, EN 10045, ISO 148, ISO 83, etc.

La máquina de brochado de muesca de muestras de impacto es un equipo especial para laboratorios físicos y químicos en metalurgia, recipientes a presión de calderas, vehículos y buques, fabricación de maquinaria de ingeniería y departamentos de investigación científica.

Parámetros

Parámetros técnicos:

1. forma de muesca de la muestra: en forma de V o en forma de U (profundidad 2 mm)

2. tamaño de la muestra de procesamiento: 10 × 10 (7,5 o 5) × 55 mm

3. Modo de transmisión: transmisión de tornillo de bola de alta precisión

4. Método de corte: eléctrico

5. Golpe del broche: 350 mm

6. Material del broche: W18Cr4V

7. Velocidad de brochado: 2.3m / min

8. Fuente de alimentación: 380V 50Hz 0.5KW de cuatro alambres trifásicos

Motor principal 0.4KW

9. Dimensiones generales: (350 × 570 × 1250) mm (longitud × ancho × altura)

10. Peso: 180kg

11. Condiciones de trabajo:

(1) Temperatura ambiente dentro de 20 ° C ± 5 ° C;

(2) Humedad relativa no superior al 85%;

(3) En un entorno sin medios corrosivos, vibración o interferencia electromagnética fuerte.

(También podemos personalizar la máquina de brochado de muesca de la muestra de impacto con profundidad de muesca de 3 mm o 5 mm de acuerdo con los requisitos del cliente)