- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

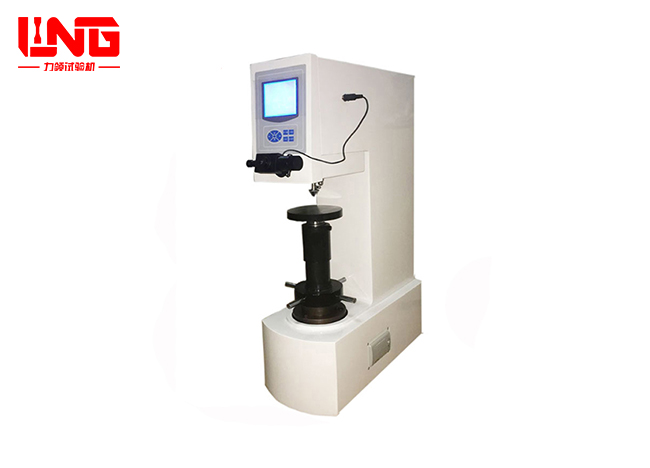

Prueba de dureza digital Vickers

El probador de dureza digital Vickers HVS-10 adopta un diseño de precisión único en mecánica, electricidad y fuente de luz, haciendo que la imagen de indentación sea más clara y la medición más precisa. Adopta pantalla LCD a color y sistema de control de microprocesador de 32 bits de alta velocidad para realizar plenamente el diálogo hombre-computadora y la operación automática. Tiene las características de alta precisión de prueba, operación simple, alta sensibilidad, fácil uso y indicación estable. Controla la aplicación automática, el mantenimiento y la eliminación de la fuerza de prueba a través del motor, y muestra directamente el valor de dureza.

Introducción

Introducción de la máquina:

El probador de dureza digital Vickers HVS-10 adopta un diseño de precisión único en mecánica, electricidad y fuente de luz, haciendo que la imagen de indentación sea más clara y la medición más precisa. Adopta pantalla LCD a color y sistema de control de microprocesador de 32 bits de alta velocidad para realizar plenamente el diálogo hombre-computadora y la operación automática. Tiene las características de alta precisión de prueba, operación simple, alta sensibilidad, uso conveniente y indicación estable. Puede aplicar, mantener y eliminar automáticamente la fuerza de prueba a través del control del motor y mostrar directamente el valor de dureza. El cuerpo del producto se forma mediante un proceso de fundición y se ha sometido a un tratamiento de envejecimiento a largo plazo. En comparación con el proceso de panelización, la deformación es extremadamente pequeña después del uso a largo plazo, y puede adaptarse eficazmente a varios entornos duros;

Características de la máquina:

l Pintura de coche, pintura de alta calidad, resistencia fuerte a los arañazos, y todavía brillante como nuevo después de años de uso;

l El sistema óptico diseñado por ingenieros ópticos superiores no solo tiene imágenes claras, sino que también se puede usar como un microscopio simple, con brillo ajustable, visión cómoda y no fácil de fatigar después de una operación a largo plazo;

l Puede realizar la conversión entre Vickers y cualquier otra escala de dureza;

l La lente objetivo de medición y observación de alta resolución, combinada con el ocular de medición digital de alta definición con codificador de longitud incorporado, realiza la medición de una sola clave de la longitud diagonal de la indentación y se deshace de los errores y problemas de entrada manual durante el proceso de lectura;

l Sistema de procesamiento de imágenes CCD opcional y dispositivo de medición de vídeo;

l Equipado con módulo Bluetooth, impresora Bluetooth y receptor opcional de PC Bluetooth para realizar la impresión inalámbrica y la transmisión inalámbrica de datos;

l La precisión cumple con GB / T4340.2 ISO6507-2 y ASTM E384 estadounidense.

Parámetros

Parámetros técnicos:

1. Rango de medición: 5-5000HV

2 Fuerza de prueba:

2.942N (0.3kgf) 4.903N (0.5kgf)

9.807N (1.0kgf) 29.42N (3.0kgf)

49.03N (5.0kgf) 98.07N (10kgf)

3. Sistema de medición óptica

Lente objetivo: 10×, 40×

Ampliación total: 100×, 400×

Rango de medición: 400 μm

Valor de graduación: 0.025μm

4. Tamaño de apariencia y fuente de alimentación

Tamaño de la apariencia: 620 * 330 * 640mm;

Altura máxima permitida de la muestra: 200mm;

Distancia desde el centro de la cabeza de presión a la pared de la máquina: 130 mm;

Fuente de alimentación: AC220V/50Hz;

Peso: 70 kg.