- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

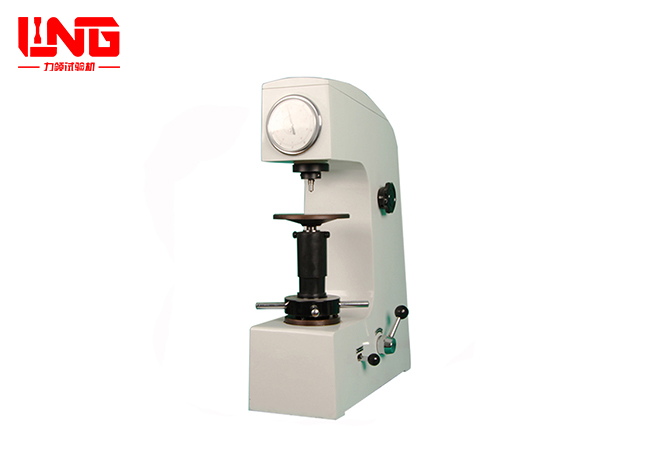

- durometro

- Solución de diseño general y planificación del laboratorio

Prueba de dureza Rockwell

La dureza, el símbolo de dureza, el tipo de indentador, el rango de prueba, etc. utilizados en la prueba de dureza de Rockwell. La dureza es un importante indicador de las propiedades mecánicas. Es la capacidad de un material para resistir otro objeto más duro con cierta forma y tamaño que no causa deformación residual para presionar en su superficie.

Introducción

Introducción del producto:

La dureza es un importante indicador de las propiedades mecánicas. Es la capacidad de un material para resistir la presión de otro objeto más duro con cierta forma y tamaño y sin deformación residual. La prueba de dureza de Rockwell es el método de prueba más rápido, sencillo y económico en la prueba de propiedades mecánicas. No solo es fácil de operar y tiene una alta eficiencia de prueba, sino que también puede obtener directamente los resultados de las pruebas. Con el rápido desarrollo de la industria de mi país, la prueba de dureza de Rockwell se ha utilizado ampliamente.

Parámetros

Parámetros técnicos:

Fuerza de prueba inicial: 98.07N (10kgf)

Fuerza de prueba total: 588.4N (60kgf) 980.7N (100kgf) 1.471KN (150kgf)

Resolución de dureza: 0.5HR

Distancia máxima del centro de indentación a la pared de la máquina: 130mm

Altura máxima de la muestra: 170mm

Dimensiones del probador de dureza: 457 × 240 × 629 mm

Peso neto del probador de dureza: 75 kg