- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

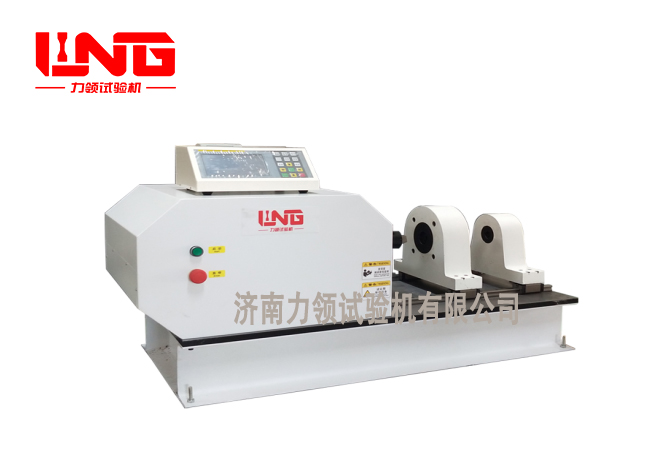

Detector automático de pernos de alta resistencia de pantalla digital

El detector automático de pernos de alta resistencia de pantalla digital LJZ-500D está diseñado y fabricado de acuerdo con los requisitos relevantes de GB50205-2020 "Código de aceptación de ingeniería de estructuras de acero", que se puede usar para pares de conexión de pernos de alta resistencia de cabeza hexagonal grande (M16, M20, M22, M24, M27, M30) y pares de conexión de pernos de alta resistencia de cizallamiento por torsión (M16, M20, M20, M30).

Introducción

El detector automático de pernos de alta resistencia de pantalla digital LJZ-500D está diseñado y fabricado de acuerdo con los requisitos relevantes de GB50205-2020 "Código de aceptación de ingeniería de estructuras de acero", que se puede usar para pares de conexión de pernos de alta resistencia de cabeza hexagonal grande (M16, M20, M22, M24, M27, M30) y pares de conexión de pernos de alta resistencia de cizallamiento por torsión (M16, M20, M20, M30).

(M22, M24) fuerza axial, par, coeficiente de par, prueba, visualización e impresión Cuando la fuerza axial alcanza el valor especificado en la norma, el detector emite un zumbidor y registra los datos de detección. Al mismo tiempo, el detector calcula automáticamente el coeficiente de par de acuerdo con la fuerza axial y el par detectados y lo muestra automáticamente.Cuando se completan un grupo de pruebas, el detector calcula automáticamente la fuerza axial media, el par medio, el coeficiente de par medio, la desviación estándar y el coeficiente de variación de N muestras. Escriba el número de prueba, tipo, grado y especificación del perno de alta resistencia, etc.

Características funcionales:

1. Este detector es un instrumento multifuncional de prueba de pernos de alta resistencia con alta precisión, función completa, diseño de apariencia excelente y diseño de estructura razonable desarrollado de acuerdo con las últimas normas nacionales.

2. Puede detectar la pretensión original, la pretensión media, el par medio, el coeficiente de par y la desviación estándar de los pernos hexagonales grandes de alta resistencia

3. También tiene las funciones de ajuste, detección, calibración, verificación, consulta, ajuste de tiempo, mantenimiento de pico de pantalla digital, descarga y visualización de semáforos de límite superior e inferior, aviso de alarma e impresión automática de datos originales y resultados de pruebas.

4. El equipo es sencillo de operar. Si se envía al departamento de medición para verificación, es conveniente llevar, y la actualización y el mantenimiento posteriores del equipo también son extremadamente convenientes.

5. Para facilitar a los usuarios conectarse con el ordenador, se configura la interfaz RS232 (Nota: Esta interfaz debe pedirse por separado); Los datos pueden transferirse a un ordenador para su posterior procesamiento y un informe impreso.

Parámetros

Parámetros técnicos:

1、 Potencia: Sistema de control: 220V AC; Servo motor: 220V potencia: 1Kw

2、Rango de detección de fuerza axial: 20-500kN

3、Rango de detección de par: 10-2000Nm

4、Especificaciones del perno: M16-M30

5、Longitud del perno: 60mm a 280mm

6、Repetibilidad: 1%

7、Resolución relativa: 0,5%