- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

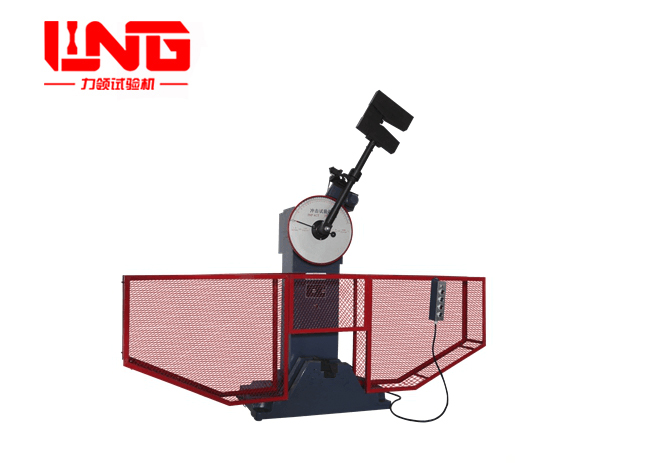

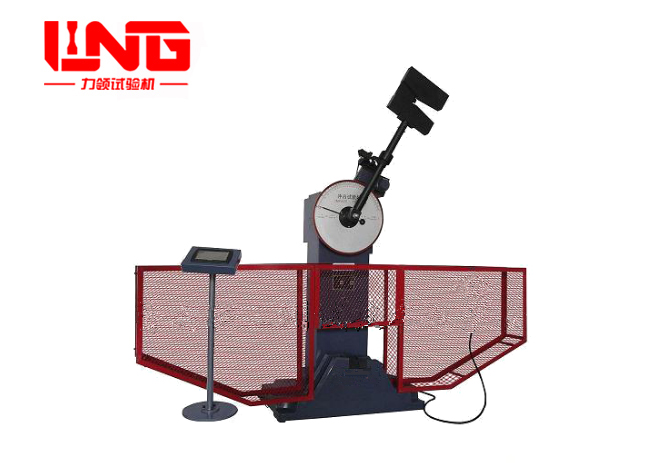

Máquina de prueba de impacto semiautomática JB-300BS

La máquina de prueba de impacto semiautomática JB-300B se utiliza para medir la resistencia al impacto de materiales metálicos bajo carga dinámica, para juzgar las propiedades de los materiales bajo carga dinámica. La diferencia entre la energía potencial antes del impacto del péndulo y la energía potencial residual después del impacto se muestra en la esfera para obtener el trabajo absorbido de la muestra.

Introducción

Introducción del producto:

La máquina de prueba de impacto semiautomática JB-300B.500B se utiliza principalmente para determinar el rendimiento de resistencia al impacto de materiales metálicos bajo carga dinámica, con el fin de juzgar el rendimiento de resistencia al impacto de materiales bajo carga dinámica. La máquina de prueba de impacto se utiliza para medir la resistencia al impacto de materiales metálicos bajo carga dinámica, para juzgar las propiedades de los materiales bajo carga dinámica. El trabajo de absorción de la muestra se obtiene utilizando la diferencia entre la energía potencial antes y la energía potencial restante después del impacto del péndulo mostrado en la esfera. La energía máxima de impacto es de 300J, y se fija un péndulo de 150J, y la sección de la muestra es de (10 x 10) mm. Esta máquina tiene una gran energía de impacto, adecuada para la resistencia al impacto de grandes metales ferrosos, como el acero y sus aleaciones. Esta máquina de control eléctrico oscilación automática, impacto y péndulo de liberación, fácil de operar, alta eficiencia. Después de perforar la muestra, la energía residual se levanta automáticamente para prepararse para la siguiente prueba de impacto, por lo que su superioridad puede reflejarse mejor en el laboratorio de prueba de impacto continua y un gran número de departamentos metalúrgicos, de fabricación de maquinaria y otros que hacen pruebas de impacto.

Parámetros

Parámetros técnicos:

Parámetro

Especificación

Energía de impacto

300 J / 150 J

Velocidad de impacto

5.2 m/s

Ángulo previo de elevación del péndulo

150°

Luz entre soportes de muestra

40 mm

Radio del soporte (esquina redondeada)

R1.0–1.5 mm

Radio del filo de impacto

R2.0–2.5 mm

Distancia centro del péndulo al punto de impacto

- Serie 300B: 750 mm

(Serie 500B: 500 J / 250 J)

- Serie 500B: 800 mm