- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

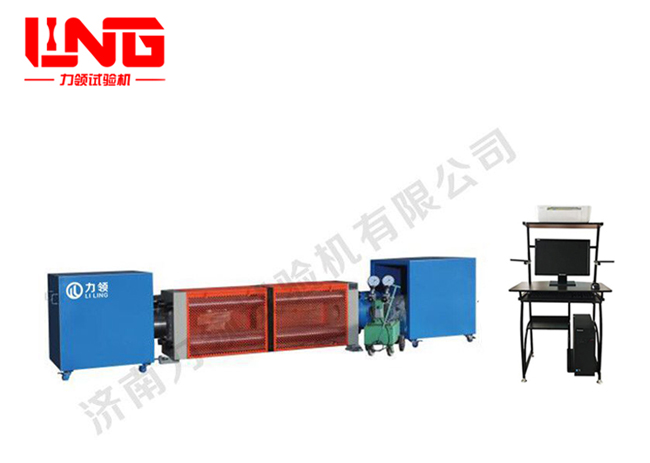

Máquina de prueba de anclaje servo electrohidráulico controlada por microordenador

La máquina de prueba de anclaje servo electrohidráulico controlada por microordenador se utiliza principalmente para el anclaje estático y las pruebas de rendimiento de carga de bajo ciclo de anclajes de hebra de acero en la construcción de puentes ferroviarios, conservación de agua, energía y otra infraestructura. Es adecuado para la inspección de prueba de rendimiento mecánico de GB / T14370 "Anclajes, abrazaderas y conectores para tendones pretensados" para determinar si las propiedades mecánicas de los anclajes de hebra de acero cumplen los requisitos especificados.

Introducción

Principales funciones y usos:

Esta serie de productos se utiliza principalmente para el anclaje de carga estática y las pruebas de rendimiento de carga de bajo ciclo de anclajes de hebra de acero en la construcción de puentes ferroviarios e infraestructura como conservación de agua y electricidad. Es adecuado para las pruebas de rendimiento mecánico de GB / T14370 "Anclajes, abrazaderas y conectores para tendones pretensados" para determinar si las propiedades mecánicas de los anclajes de hebra de acero cumplen los requisitos especificados.

Ventajas del producto:

u Diseño razonable, fácil de usar, alta precisión de medición y control.

u El circuito cerrado servo electrohidráulico se utiliza para realizar el control del proceso de prueba de carga de velocidad constante y retención de carga, asegurando que la velocidad de carga sea estable y fiable, proporcionando precisión de retención de carga y evitando la influencia de factores humanos en los resultados de la prueba.

u El sistema tiene un mecanismo de carga de gran tonelaje y sistema automático de detección de valor de fuerza, que puede cumplir con los requisitos de prueba de rendimiento de anclaje de carga estática.

u El microordenador se utiliza para el control automático, la recolección automática, el almacenamiento y el procesamiento de los datos de prueba. Durante la prueba, la pantalla del ordenador muestra la curva de prueba en tiempo real, detecta los cambios en la fuerza y el desplazamiento, calcula automáticamente la contracción e imprime la curva de prueba y los datos de prueba.

Parámetros

Main specifications and technical parameters:

Parámetro

MGW-5000

MGW-6500

Rango efectivo de medición de fuerza

2% – 100%

No especificado

Error relativo de indicación de fuerza

±1%

±1%

Rango de medición de desplazamiento (mm)

0 ~ 200

No especificado

Error relativo de indicación de desplazamiento

±1%

No especificado

Rango de ajuste de velocidad de fuerza

1 MPa – 52 MPa

No especificado

Error relativo de control de velocidad de fuerza

±1%

No especificado

Error relativo de control de velocidad de desplazamiento

±1%

No especificado

Rango de control de fuerza/desplazamiento

0.3% – 100% F·S

No especificado

Error relativo de mantenimiento de fuerza/desplazamiento

±1%

No especificado

Repetibilidad

±0.5%

No especificado

Resolución relativa

±0.5%

No especificado

Carrera del pistón (mm)

200

No especificado

Distancia de tracción (mm)

3200

No especificado

Dimensiones (mm)

3200 × 780 × 650

3300 × 750 × 660

Peso (kg)

3000

5000