- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

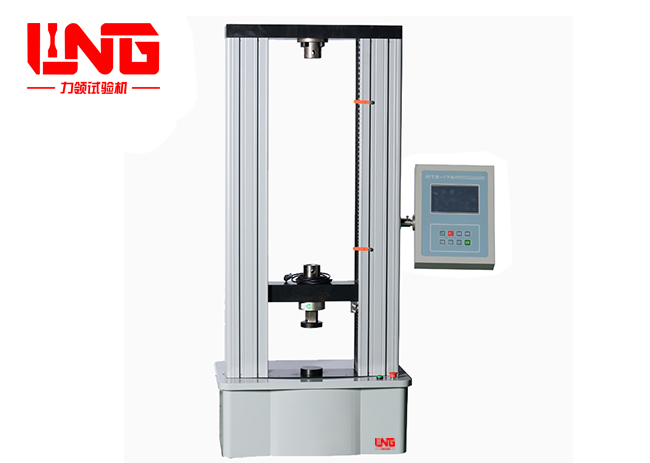

Máquina de prueba universal servohidráulica electrohidráulica controlada por microordenador

La máquina de prueba universal servo electrohidráulica controlada por microordenador adopta el tipo inferior del cilindro y la máquina principal de cuatro columnas, que se utiliza principalmente para la prueba de tracción, compresión, flexión y cizallamiento de metal y no metal. Adecuado para metalurgia, construcción, industria ligera, aviación, aeroespacial, materiales, colegios y universidades, instituciones de investigación científica y otros campos. La operación de prueba y el procesamiento de datos cumplen los requisitos de GB228-2002/2010 "Método de prueba de tracción para materiales metálicos a temperatura ambiente".

Introducción

Introducción del producto:

La máquina de prueba universal servo electrohidráulica controlada por microordenador adopta el tipo inferior del cilindro y la máquina principal de cuatro columnas, que se utiliza principalmente para la prueba de tracción, compresión, flexión y cizallamiento de metal y no metal. Adecuado para metalurgia, construcción, industria ligera, aviación, aeroespacial, materiales, colegios y universidades, instituciones de investigación científica y otros campos. La operación de prueba y el procesamiento de datos cumplen los requisitos de GB228-2002/2010 "Método de prueba de tracción para materiales metálicos a temperatura ambiente".

Parámetros

Especificación técnica:

|

Parámetro |

BAT-3000 |

BAT-0000 |

BAT-1000D |

BAT-2000D |

|

Fuerza máxima de prueba |

300 kN |

- |

1000 kN |

2000 kN |

|

Rango de medición de fuerza |

3 kN ~ 300 kN |

CKS-000* |

100 kN ~ 1000 kN |

200 kN ~ 2000 kN |

|

Precisión de fuerza |

±0.5% |

- |

- |

- |

|

Resolución de desplazamiento |

0.01 mm |

- |

- |

- |

|

Medición de deformación |

±0.5% |

- |

- |

- |

|

Control de precisión |

±1.0% (10.98s) |

- |

- |

- |

|

Espacio máximo de tracción |

800 mm |

800 mm |

50 mm |

800 mm |

|

Espacio de cooperación máximo |

700 mm |

700 mm |

700 mm |

700 mm |

|

Espesor de sujeción para probetas planas |

0-15 mm |

0-15 mm |

0-40 mm |

0-60 cm* |

|

Diámetro de probetas circulares |

Φ13 mm ~ Φ70 mm* |

Φ13 mm ~ Φ70 mm* |

Φ13 mm ~ Φ70 mm* |

Φ15 mm ~ Φ70 mm |

|

Pruebas de flexión |

|

|

|

|

|

- Distancia entre rodillos |

450 mm |

- |

- |

140 cm |

|

- Diámetro del fulcro |

30 cm |

- |

- |

- |

|

Carrera del pistón |

250 mm |

- |

- |

- |

|

Modo de sujeción |

Sujeción hidráulica integrada |

- |

- |

- |

|

Dimensiones principales |

|

|

|

|

|

- Unidad principal |

990×600×2453 mm |

1160×1100×2000 mm* |

990×600×2453 mm |

1100×770×2490 mm |

|

- Fuente de aceite |

1100×700×950 mm |

- |

- |

- |

|

Peso total |

- |

- |

- |

|