- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

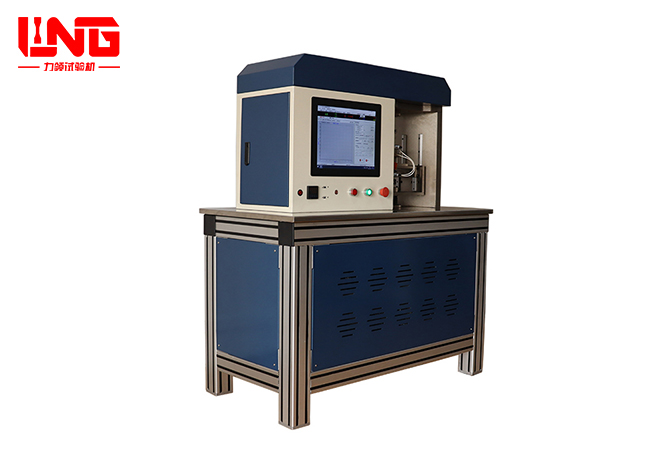

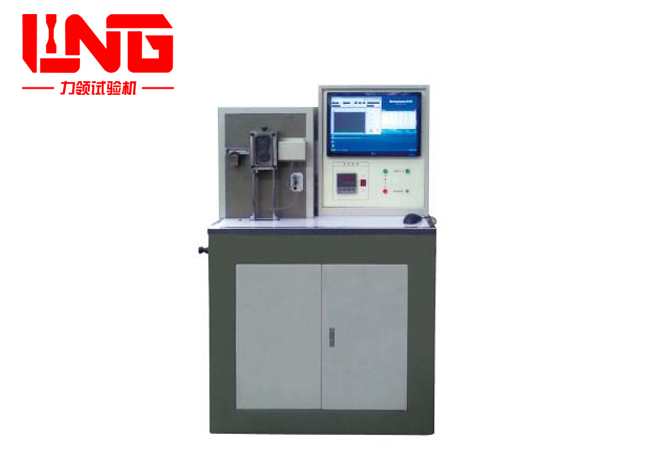

Máquina de prueba de fricción y desgaste de extremo

El probador de fricción y desgaste de cara extrema MMU-5/10/20 realiza principalmente la fricción deslizante entre la cara extrema y el disco de pasador (también puede expandir otros pares de fricción de acuerdo con los requisitos de uso), y pruebas bajo diversas condiciones como el cambio del estado de lubricación (lubricación sin aceite o lubricación sumergida en aceite), carga, velocidad, material de pareja de fricción, rugosidad superficial del par de fricción, dureza y otros parámetros.

Introducción

Presentación del producto:

Nuestra empresa se especializa en fricción y desgaste, desarrollo de equipos de prueba de evaluación de lubricación e investigación de tecnología de prueba. La producción principal de la serie de máquinas de prueba de fricción de cuatro bolas, la serie de máquinas de prueba de desgaste final, la serie de máquinas de prueba de fricción y desgaste de bloques de anillo, la serie de máquinas de prueba de fricción y desgaste a largo plazo, la serie de máquinas de prueba de fricción y desgaste de rodamientos lisos y la alta temperatura, el vacío, la corrosión y otras funciones especiales de la máquina de prueba de fricción y desgaste Un total de más de 30 especificaciones y variedades, un total de más de 30 especificaciones y variedades. Ampliamente utilizado en la industria petroquímica, colegios y universidades y tribología en varios campos profesionales.

Máquina de prueba de fricción y desgaste del extremo MMU-5/10/20, realiza principalmente la fricción deslizante como la cara del extremo y el disco del pasador (otros pares de fricción también se pueden expandir de acuerdo con los requisitos de uso, Cambiar el estado de lubricación (libre de aceite o sumergido en aceite) 、 Carga, velocidad, material de fricción, rugosidad de la superficie del par de fricción, dureza y otros parámetros se prueban en varias condiciones. Se puede utilizar para evaluar el rendimiento de desgaste de varios metales, recubrimientos, plásticos de ingeniería, cerámica y metalurgia de polvo y otros materiales nuevos, y para determinar las características anti-desgaste y de coincidencia de materiales de sus materiales. La máquina de prueba tiene un espacio de expansión de par de fricción, puede expandir una variedad de formas de contacto, una variedad de condiciones de trabajo especiales, para satisfacer las necesidades de investigación científica de diferentes clientes.

El equipo se utiliza principalmente para evaluar las propiedades de fricción de materiales de ingeniería, metalurgia de polvo, rodamientos de aleación y otros materiales en diferentes condiciones, y se puede aplicar a la selección de materiales de par de fricción y el estudio de las propiedades anti-desgaste de los materiales.

Parámetros

Especificación técnica:

|

N.º |

Nombre del proyecto |

Índice técnico |

|

1 |

Modelo del producto |

MMU-5 / MMU-10 / MMU-20 |

|

2 |

Rango de fuerza de prueba |

50~5000 N (MMU-5) |

|

3 |

Precisión de fuerza de prueba |

±1% |

|

4 |

Rango de velocidad del huso |

1~2000 r/min |

|

5 |

Error de velocidad del huso |

±1 r/min |

|

6 |

Fuerza de fricción máxima |

1000 N |

|

7 |

Precisión de medición de fricción |

≤±1% |

|

8 |

Temperatura |

Ambiente ~260°C |

|

9 |

Rango de tiempo (visualización/control) |

1~999999 s/min/h |

|

10 |

Rango de velocidad (visualización/control) |

1~9999999999 |

|

11 |

Modo de registro de datos |

Pantalla LCD + registro en computadora |

|

12 |

Par de fricción de prueba |

Anillo de muestra: Φ26 × Φ20 ×12 mm |

|

13 |

Modo de control de fuerza |

Manual + control en bucle cerrado con motor servo de CA |

|

14 |

Peso |

≈800 kg |

|

15 |

Dimensiones (L × A × H) |

1200 × 870 × 1700 mm |