- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

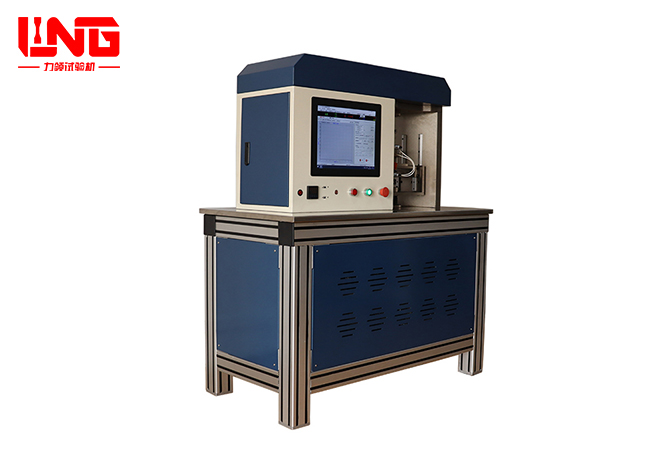

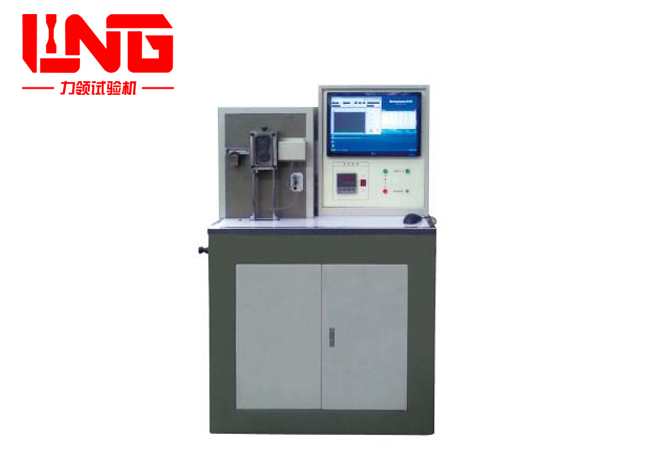

Máquina de prueba de fricción y desgaste universal vertical controlada por microordenador

La máquina de prueba de fricción y desgaste universal vertical controlada por microordenador utiliza principalmente formas de deslizamiento, laminación y fricción combinada, y selecciona diferentes formas de par de fricción bajo baja presión de contacto para evaluar el rendimiento anti-desgaste a largo plazo de aceites y grasas lubricantes, así como el rendimiento de fricción y desgaste de materiales metálicos.

Introducción

Introducción del producto:

Esta máquina utiliza principalmente formas de deslizamiento, laminación y fricción compuesta, y selecciona diferentes formas de par de fricción bajo baja presión de contacto para evaluar el rendimiento anti-desgaste a largo plazo de aceites y grasas lubricantes, así como el rendimiento de fricción y desgaste de materiales metálicos. La máquina está equipada con tres tipos de pares de fricción, incluyendo cuatro bolas, disco de pin y anillo de empuje. De acuerdo con las necesidades del usuario, puede proporcionar varias formas de par de fricción como disco de bola, bola de tres piezas, columna de pin de tres, leva simulada, engranaje, etc. La máquina puede medir el par de fricción, calcular el coeficiente de fricción, conectarse al ordenador y registrar la curva temperatura-tiempo y la curva coeficiente de fricción-tiempo. La máquina está equipada con un dispositivo de medición de alta precisión, que puede medir el tamaño del punto de desgaste del par de fricción, o realizar la pantalla de computadora, la medición y la grabación del punto de desgaste del par de fricción.

Parámetros

Parámetros técnicos:

1. Fuerza de prueba máxima: 1000N;

2. Error relativo de la indicación de la fuerza de prueba: ±1%;

3. Valor máximo de la prueba de par de fricción: 2.5Nm;

4. Rango de velocidad del husillo: 10 ~ 1500r / min;

5. Rango de control de temperatura de la muestra: temperatura ambiente ~ 150 ℃;

6. Dimensiones generales (longitud × ancho × altura) mm: 860mm × 740mm × 1600mm;

7. Se puede conectar a una grabadora para registrar curvas de tiempo de temperatura y par de fricción.