- Máquina de prueba de fatiga dinámica

- Máquina de prueba de fricción y desgaste

- Máquina de prueba especial del sujetador

- Máquina de prueba de propiedades mecánicas estáticas

- Máquina de prueba de tracción in situ

- Equipo mecánico grande y pequeño personalizado no estándar

- Equipo de preparación y análisis de muestras metalográficas

- durometro

- Solución de diseño general y planificación del laboratorio

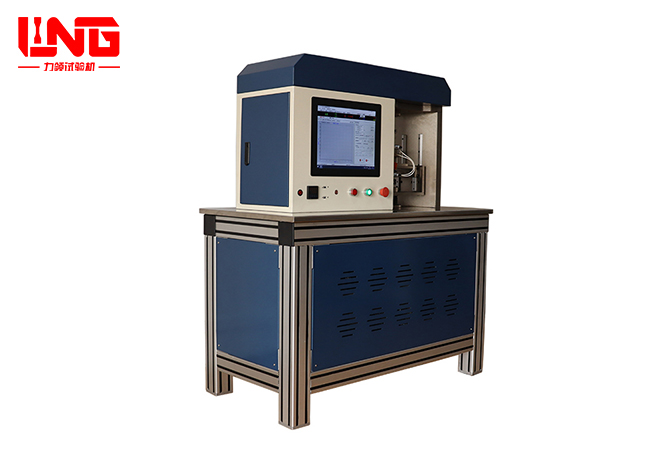

Máquina de prueba de fricción y desgaste de ruedas de goma de arena húmeda y seca

La empresa de máquina de prueba Liling se centró en la producción de máquina de prueba de fricción y desgaste durante más de diez años, excelencia técnica, proceso constantemente actualizado y mejorado, máquina de prueba de desgaste abrasivo es muy popular entre los usuarios, después del uso también está muy satisfecho!

Introducción

Introducción del producto:

el aparato de arena seca/rueda de goma1 cumple con los requisitos de ASTM-G65 (Método de prueba estándar para medir la abrasión utilizando el aparato de arena seca/rueda de goma1). También cumple con JBT_7705-1995 (método de prueba de desgaste abrasivo suelto). Método de rueda de goma) requisitos estándar. Esta máquina es una máquina de prueba de desgaste abrasivo semilibre para arena seca y húmeda. El principio de trabajo de la prueba de arena húmeda: Utiliza la rotación en sentido contrario a las agujas del reloj de la rueda de goma para impulsar el mineral, la arena, la arena y otros abrasivos para desgastar varios materiales metálicos o no metálicos, para probar la resistencia al desgaste del material. El principio de trabajo de la prueba de arena seca: la arena de cuarzo cae libremente a lo largo de la boquilla metálica, y la rueda de goma giratoria en el sentido horario acciona la arena de cuarzo (arena mineral, arena, arena) y otros abrasivos para desgastar varios materiales metálicos o no metálicos, para llevar a cabo la prueba de resistencia al desgaste en el material.

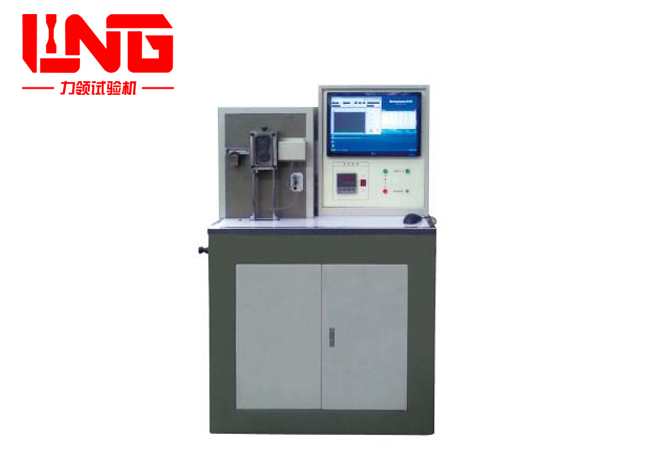

Parámetros

Parámetros técnicos:

1, la máquina de carga máxima 225 Newton

2, la dirección de rotación de la rueda de goma en sentido antihorario, en sentido horario

3, velocidad de la rueda de goma 181/240/374/498

4, el diámetro de la rueda de goma es de 178 mm

5, dureza de la rueda de goma 60, 70 (dureza de la costa)

6, relación de mortero 1000g agua 1500g arena

7, tamaño de la muestra longitud × ancho × grosor = 57 × 25,5 × 6 (mm)

8, dimensiones generales (longitud × ancho × altura) 710 × 740 × 1600 (unidad mm)

9. Peso: 500kg